Applied Materials and BE Semiconductor Industries to Accelerate Chip Integration Technology for the Semiconductor Industry

22 Octobre 2020 - 7:00AM

Applied Materials, Inc. and BE Semiconductor Industries N.V. (Besi)

today announced an agreement to develop the industry’s first

complete and proven equipment solution for die-based hybrid

bonding, an emerging chip-to-chip interconnect technology that

enables heterogeneous chip and subsystem designs for applications

including high-performance computing, AI and 5G.

As traditional 2D scaling slows, the semiconductor industry is

shifting towards heterogeneous design and chip integration as a new

way to deliver improvements in performance, power, area/cost and

time-to-market (PPACt). To accelerate this trend, Applied and Besi

have formed a joint development program and are establishing a

Center of Excellence focused on next-generation chip-to-chip

bonding technology. The program harnesses the companies’ respective

front- and back-end semiconductor expertise to deliver co-optimized

integrated hybrid bonding configurations and equipment solutions

for customers.

“Challenges in conventional Moore’s Law scaling are straining

the economics and pace of the semiconductor industry’s roadmap,”

said Nirmalya Maity, Corporate Vice President of Advanced Packaging

at Applied Materials. “Our collaboration with Besi and the

formation of a new Hybrid Bonding Center of Excellence are key

components of Applied’s strategy to equip customers with a ‘New

Playbook’ for driving improvements in PPACt. Applied looks forward

to working with Besi to co-optimize our equipment offerings and

accelerate advanced heterogeneous integration technology for our

customers.”

“We are excited about forming this unique joint development

program with Applied Materials which brings together the

semiconductor industry’s leading materials engineering and advanced

packaging technologies for customers,” said Ruurd Boomsma, CTO of

Besi. “Our collaboration can greatly accelerate the adoption and

proliferation of hybrid bonding for leading-edge 5G, AI,

high-performance computing, data storage and automotive

applications.”

Hybrid bonding connects multiple “chiplets” in die form using

direct, copper interconnects. This technique enables designers to

bring chiplets of various process nodes and technologies into

closer physical and electrical proximity so that they perform as

well or better than if they were made on a single large, monolithic

die. Hybrid bonding is a major improvement over conventional chip

packaging because it permits increased chip density and shortens

the lengths of the interconnect wiring between chiplets, thereby

improving overall performance, power, efficiency and cost.

A complete die-based hybrid bonding equipment solution requires

a broad suite of semiconductor manufacturing technologies along

with high-speed and extremely precise chiplet placement technology.

To achieve this, the joint development program brings together

Applied’s semiconductor process expertise in etch, planarization,

deposition, wafer cleaning, metrology, inspection and particle

defect control with Besi’s leading die placement, interconnect and

assembly solutions.

The Center of Excellence will be located at Applied’s Advanced

Packaging Development Center in Singapore which is one of the

industry’s most advanced wafer-level packaging labs. It enables the

foundational building blocks of heterogenous integration in a

17,300-square-foot Class 10 cleanroom with full lines of

wafer-level packaging equipment. The Center of Excellence will

provide customers a platform to accelerate the development of

custom hybrid bonding test vehicles including design, modeling,

simulation, fabrication and testing.

About Applied MaterialsApplied Materials,

Inc. (Nasdaq: AMAT) is the leader in materials engineering

solutions used to produce virtually every new chip and advanced

display in the world. Our expertise in modifying materials at

atomic levels and on an industrial scale enables customers to

transform possibilities into reality. At Applied Materials,

our innovations make possible the technology shaping the future.

Learn more at www.appliedmaterials.com.

About Besi Besi is a leading supplier of

semiconductor assembly equipment for the global semiconductor and

electronics industries offering high levels of accuracy,

productivity and reliability at a low cost of ownership. The

Company develops leading edge assembly processes and equipment for

leadframe, substrate and wafer level packaging applications in a

wide range of end-user markets including electronics, mobile

internet, cloud server, computing, automotive, industrial, LED and

solar energy. Customers are primarily leading semiconductor

manufacturers, assembly subcontractors and electronics and

industrial companies. Besi’s ordinary shares are listed on Euronext

Amsterdam (symbol: BESI). Its Level 1 ADRs are listed on the OTC

markets (symbol: BESIY Nasdaq International Designation) and its

headquarters are located in Duiven, the Netherlands. For more

information, please visit our website at www.besi.com.

Contact:

Applied Materials:

Ricky Gradwohl (editorial/media) 408.235.4676Michael Sullivan

(financial community) 408.986.7977

Besi:

Richard W. Blickman, President & CEOHetwig van Kerkhof, SVP

FinanceTel. (31) 26 319 4500investor.relations@besi.com

A photo accompanying this announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/329a55cf-4f0c-4f83-a79a-f29eb93f30b5

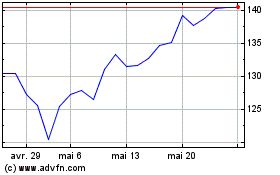

Be Semiconductor Industr... (EU:BESI)

Graphique Historique de l'Action

De Oct 2024 à Nov 2024

Be Semiconductor Industr... (EU:BESI)

Graphique Historique de l'Action

De Nov 2023 à Nov 2024