Marimaca Copper Corp. (“Marimaca Copper” or the “Company”) (TSX:

MARI) is pleased to announce results of the variability test work

metallurgical program (the “Variability Program” or the “Program”)

for the Company’s flagship Marimaca Copper Project (“Marimaca” or

“the Project”), located in northern Chile. The variability test

work was completed as a component of the Company’s ongoing Phase 5

Metallurgical program and additional associated studies, which are

expected to be completed in early Q1 2022. The ongoing 2021

metallurgical campaign is focused on finalizing the metallurgical

characterization of the Project to a bankable level and builds on

the results from the Phase 4 Metallurgical program

(see

September 9 2020 announcement).

The Variability Program was designed to

investigate the variability of the Marimaca ore body by assessing

copper recovery, acid consumption and impurity dissolution

characteristics within each mineralogical domain (ore type). This

Program represents an important de-risking milestone for Marimaca

by increasing certainty and predictability of the metallurgical

response for each ore type and spatially across the deposit, and to

refine process design criteria prior to the Feasibility Study

targeted for 2022.

Highlights

- Results from the

Variability Program demonstrate uniform metallurgical behaviour

within each mineral zone when considering acid consumption and

copper recoveries

- A total of 412

composites across each of the 5 mineral zones within the Marimaca

Mineral Resource (Brochantite, Chrysocolla, WAD, Mixed and

Enriched) were analyzed

- Results

significantly improve the resolution of the Marimaca

geo-metallurgical model and will allow for rigorous modeling of

recovery and acid consumption across mine blocks ahead of the

planned 2022 Feasibility Study

- The Program is a

core component of the Company’s Phase 5 metallurgical testing

program, the second program undertaken since the 2020 Preliminary

Economic Assessment (“PEA”) (refer to announcement on 4

August 2020), which projected average life of mine

metallurgical recoveries in the heap leach of approximately

76%

- For the oxide

mineral zones (BROC, CRIS, WAD), recoveries generally exceeded the

solubility ratio and leaching potential of the samples (see

Leaching Potential Overview), indicating a potentially larger

proportion of the copper is acid soluble and will be recovered in

commercial-scale heap leaching

- The Variability

Program represents a significant de-risking milestone and will form

the basis for defining recovery and processing assumptions for

Feasibility Study and eventual operational mine plans

- MOD infill

drilling is underway, and MOD Depth Extension (MAMIX) infill

drilling is currently being planned

Hayden Locke, President and CEO of

Marimaca Copper, commented:

“One of the key risks of any project is

variability in the metallurgical performance of a deposit when

moving laterally or vertically. We have completed an incredibly

rigorous programme encompassing over 400 hundred samples spread

evenly across the deposit in both vertical and horizontal

directions. This provides us with a significant amount of data to

underpin our assumptions with respect to both the expected copper

recoveries and acid consumption of each mining block.

“Importantly, the programme continues to give us

a high degree of confidence that the assumptions used in our 2020

PEA, with respect to copper recoveries and acid consumptions, are

valid. In fact, we have identified several areas for optimization

and may see some improvement relative to the PEA assumptions.

“We have commenced the infill drilling campaign

for the MOD and are currently planning for infill drilling the

recently discovered deeper extensions of the MOD (MAMIX). The

objective is to bring additional copper tonnes into an eventual

updated Mineral Resource Estimate in the first half of 2022, which

we will use as the basis for our Feasibility Study.”

Program Overview

A total of 412 variability composite samples

were selected and analyzed for the Program. Samples were selected

using spatial criteria across the PEA open-pit mineable resource

area, subdivided into macroblocks of 75m x 75m x 25m (Figure 1). A

total of 4,491 RC samples were processed through rigorous

variability criteria screening and formed the basis for the 412

composites.

The program design consisted of three

components:

- Chemical Head

Characterization.

- Characterization

included sequential copper analysis, leaching potential, soluble

impurities, analytic acid consumption, and others

- Iso-pH Bottle Roll

Tests

- Conducted under

constant pH and Cl conditions to examine the correlation to the

analytical acid consumption (AAC) diagnostic testing method,

improve the acid consumption modeling, and review copper recovery

relative to leaching potential

- 3 Acid Level

Sensitivity Bottle Roll Test

- Conducted to

examine copper recovery and acid consumption sensitivity relative

to acid concentration

Figure 1. Composite Sample Mineral Subzones

https://www.globenewswire.com/NewsRoom/AttachmentNg/2006a981-cf48-48b0-87ec-a4a14aab6efe

Results Discussion

Analytical Acid Consumption

(AAC)

The average total AAC of the sample population

was 40.79 kg/t with <10% of the samples returning an AAC of

>60 kg/t. Green oxides tend to have a higher acid consumption

than the balance of the mineral subzones (45-50 kg/t relative 30-40

kg/t). This difference is explained by marginal incremental

carbonate content relative to WAD, MIX and ENR. All mineral

subzones present low AAC variability and the same consistency was

observed across the additional soluble impurities tested as part of

the Analytical Acid Consumption assay (Fe, Al, Mg, Mn). In general,

uniform behavior is observed within the mineral subzones.

Figure 2. Analytical Acid Consumption

Test

https://www.globenewswire.com/NewsRoom/AttachmentNg/f875c978-4e30-46c4-9c98-c79459e0a0b0

Iso-pH tests

Similar to results observed in the Phase 4

metallurgical program, the majority of the composite samples

returned recoveries that exceeded the solubility ratio, indicating

that all of the acid soluble copper was recovered as well as

additional copper not reported in the soluble copper assays.

Additionally, the BROC, CRIS and WAD samples generally returned

recoveries that exceeded the leaching potential, while the MIX and

ENR samples reached recoveries between the solubility ratio and the

leaching potential. WAD demonstrates the greatest recovery margin

above the leaching potential. Currently this is interpreted as the

presence of black oxides that are not detected in the head

characterization tests but it can be recovered in longer tests

given their slower leach kinetics. This can also be observed in the

BROC and CRIS subzones, but to a lesser extent. Results observed

for the MIX and ENR samples are as expected for the test

conditions, as, to achieve higher recoveries of secondary sulfides,

longer leach time or additional agglomeration and curing stages are

required to increase recoveries.

Figure 3. Copper recovery vs. leaching

potential

https://www.globenewswire.com/NewsRoom/AttachmentNg/202f9a48-0866-45b3-9020-4ce797517bbd

The iso-pH acid consumption test also demonstrated a strong

correlation between when compared with the AAC test which provides

strong validation for the results.

Figure 4. Acid consumption – AAC method vs.

Iso-pH results

https://www.globenewswire.com/NewsRoom/AttachmentNg/aba392a8-f601-4709-a250-1e73fce77fdb

3 Acid Level Sensitivity

Test

Copper recoveries did not demonstrate

significant sensitivity to acid level test between 2.5 gpl, 5 gpt

and 10 gpl. A slightly higher copper recovery is observed with

higher acidity, but the effect is very limited. The sensitivity of

acid consumption to acid level was higher than the copper recovery

sensitivity. Acid consumption decreases materially at lower

acidity. This is a known characteristic of the Marimaca ore and

will play an important role in the processing plant operating

condition design. Follow up tests are currently being designed to

investigate further.

Figure 5. Acid level

sensitivities

https://www.globenewswire.com/NewsRoom/AttachmentNg/f6e418eb-383c-4824-848f-e82a9c009a3b

Overview of Leaching

Potential

The leaching potential of copper ores is defined

as acid soluble copper (CuS) plus cyanide soluble copper (CuCN)

divided by total copper (CuT). The acid solubility ratio (CuS/CuT)

for copper oxides such as atacamite, brochantite and chrysocolla,

which dissolve quickly when exposed to acid, is a good predictor of

leachability. However, where the mineralization has several copper

bearing minerals with different dissolution characteristics under

these leaching conditions, the copper acid solubility ratio may

materially underestimate the acid leaching potential for heap leach

operations, especially where some copper sulphides such as

chalcocite, covellite and bornite are present, as these sulphides

can be partially dissolved under oxidation conditions.

For this reason, it is common to assay for

cyanide soluble copper when assaying leachable copper

mineralization. This gives an indication of the total leaching

potential [(CuS + CuCN)/CuT] because cyanide dissolves some of the

copper sulphides that may be present in the sample and assumes

that, during the leaching operation, some oxidation reactions, such

as, ferric leaching and/or cupric chloride leaching occur. Due to

these reactions during sulphide leaching it can be inferred that

copper dissolution in a leaching operation may materially exceed

the copper acid solubility ratio identified.

Marimaca has conducted five phases of

metallurgical testing and has noted that in several mineral

subzones, especially those with higher proportions of black copper

oxides, the metallurgical recovery has exceeded the leaching

potentials identified in sequential copper analysis.

Qualified Person

The Qualified Person for technical information in

this news release is Marcelo Jo, General Manager of Jo y Loyola

Process Consulting, a chemical engineer with more than 35 years of

experience and a Fellow of Chilean Mining Engineers Institute.

Metallurgical Qualified Person according the Chilean Mining

Committee for the purposes of NI 43-101.

The QP confirms they have visited the project area,

have reviewed relevant project information, is responsible for the

information contained in this news release, and consents to its

publication.

Contact InformationFor further

information please visit www.marimaca.com or contact:

Tavistock +44 (0) 207 920

3150Jos Simson/Oliver Lamb / Nick

Elwesmarimaca@tavistock.co.uk

Forward Looking Statements

This news release includes certain

“forward-looking statements” under applicable Canadian securities

legislation. There can be no assurance that such statements will

prove to be accurate, and actual results and future events could

differ materially from those anticipated in such statements.

Forward-looking statements reflect the beliefs, opinions and

projections on the date the statements are made and are based upon

a number of assumptions and estimates that, while considered

reasonable by Marimaca Copper, are inherently subject to

significant business, economic, competitive, political and social

uncertainties and contingencies. Many factors, both known and

unknown, could cause actual results, performance or achievements to

be materially different from the results, performance or

achievements that are or may be expressed or implied by such

forward-looking statements and the parties have made assumptions

and estimates based on or related to many of these factors. Such

factors include, without limitation: risks related to share price

and market conditions, the inherent risks involved in the mining,

exploration and development of mineral properties, the

uncertainties involved in interpreting drilling results and other

geological data, fluctuating metal prices, the possibility of

project delays or cost overruns or unanticipated excessive

operating costs and expenses, uncertainties related to the

necessity of financing, the availability of and costs of financing

needed in the future as well as those factors disclosed in the

annual information form of the Company dated March 29, 2021, the

final short form base prospectus and other filings made by the

Company with the Canadian securities regulatory authorities (which

may be viewed at www.sedar.com). Accordingly, readers should

not place undue reliance on forward-looking statements. Marimaca

Copper undertakes no obligation to update publicly or otherwise

revise any forward-looking statements contained herein whether as a

result of new information or future events or otherwise, except as

may be required by law.

Neither the Toronto Stock Exchange nor the

Investment Industry Regulatory Organization of Canada accepts

responsibility for the adequacy or accuracy of this

release.

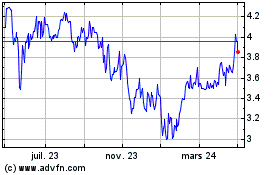

Marimaca Copper (TSX:MARI)

Graphique Historique de l'Action

De Mar 2024 à Avr 2024

Marimaca Copper (TSX:MARI)

Graphique Historique de l'Action

De Avr 2023 à Avr 2024