Transforming the Built Environment with Circular Design Technology

26 Août 2024 - 3:00PM

Aquafil SpA (ECNLF:OTCQX – ECNL:IM), based in Arco

(TN) Italy and a pioneer of the circular economy, today released

its second in a series of monographs that illustrate how we can

design better to do better.

The potential for technology to revolutionize

the way we live and work is boundless. In this context, the

intersection of sustainability and technology presents a compelling

growth opportunity. Companies that prioritize eco-design and

circular manufacturing practices are not only driving positive

environmental outcomes but also positioning themselves at the

forefront of a rapidly expanding market segment. But, in the

context of circular design, the key drivers of this transformation

are not just AI or advanced tools, but the designers,

manufacturers, and producers who wield them. True power for change

lies within the human mind, capable of reimagining and reshaping

design. When creative minds and cutting-edge technology come

together, the opportunity to transform industries is

immense—especially within the built environment. Aquafil is an

industry leader with a legacy of innovation in sustainable design,

exemplifying how businesses can capitalize on these trends. The

kernel of all change is concept and design. In the circular

economy, therefore, it all starts with design, and here are some of

the ways design can support circular technology.Stage 1:

Designing with the End in MindEco-design is the process of

minimizing environmental impact by designing a product with

circularity in mind at inception. While designing a product,

consider what is going to happen at the end of its life – tossed

into a landfill, or recycled into new ingredients for new

designs?One of the essential elements is to design products where

its materials are easily separated and recycled after use at the

design stage. This means making it easy to remove the nylon tufts

from carpet backing, or separating the metal zipper from a nylon

jacket so the nylon can be recycled or, better, regenerated.Not

only do products need to be creatively designed to be easily

separated, but the technology that can produce these eco-designed

pieces also needs to be developed. For instance, Aquafil started

with the flooring industry where it launched the R2R project in

partnership with our customers to co-design the environmental

friendly flooring of the future.Stage 2: Creating Circular

IngredientsThe world has become reliant on plastic

products, which are made by extracting oil and gas, and are often

designed to only be used once. Every year, millions of tons of

plastic ends up in landfills or, worse, irresponsibly dumped into

our oceans. There is an opportunity to reduce our reliance on

resource extraction and eliminate waste by creating circular

plastic ingredients. Aquafil has developed ECONYL® regenerated

polymers that can also be used in place of hard plastics made from

oil. The versatility of ECONYLⓇ regenerated polymers makes the

ingredient ideal for injection molding, extrusion and production of

products like chairs or frames for sunglasses.

The beauty of these polymers is that, unlike the

limited life of most plastics that are recycled, they can be

infinitely regenerated for endless use - circular. In addition, the

development of this technology not only reduces production waste

but also aligns with global sustainability goals—trends that are

increasingly important to both consumers and regulators.

Stage 3: Developing Circular

Manufacturing Practices

Once we have a product made of recyclable

ingredients that can easily be separated for continued recycling

and regeneration, we need a circular manufacturing model to reduce

waste during production. One of the latest technologies getting

interest is circular additive manufacturing, or 3D printing.

3D printing currently only makes up about 1% of

the global manufacturing market, but it is set to grow

exponentially. This is a great opportunity for designers to utilize

3D printing to create more sustainable products since it is an

additive process, meaning it builds a product by adding materials

as needed rather than creating waste by removing what isn’t

needed.

In addition to reducing the amount of waste

during production, 3D printing can also reduce waste by enabling

designers to create more effective prototypes through the digital

system, make and replace parts as needed, and manufacture in

multiple locations instead of shipping from one central plant. 3D

printing can be even more sustainable when designers elect to print

with recycled plastics, like ECONYL® regenerated polymers and

filaments. To evolve into a truly circular economy we must continue

to learn and innovate, that is why Aquafil, in the last year alone,

invested almost 2% of revenues in R&D.

Do not miss the latest updates by tuning in to

the Aquafil Group’s 1H 2024 Results which will be presented on

Thursday, 29th August 2024 at 12.00 PM ET, live on YouTube (the

link to the conference call will be available on the IR calendar:

https://www.aquafil.com/investor-relations/financial-calendar/).

About Aquafil SpA

Since 1965, the Aquafil Group has been a pioneer

of the circular economy and a landmark in terms of quality and

product innovation for Italy and the globe. We primarily

manufacture Nylon 6 fibers and polymers but also Nylon 6.6 and

Dryarn. Our flagship product is ECONYL® nylon, which revolutionizes

the world of synthetic fibers through a closed-loop model.

Today, Aquafil remains a leader in the research

of new production systems for sustainable development.

To keep current on Aquafil, please go to

www.aquafil.com.

Investors ContactGiulia Rossi

investor.relations@aquafil.com mob: +39 327 0820.268

Media Contact Maria Giovanna

Sandrini maria.giovanna.sandrini@aquafil.commob: +39 348

6019.628

U.S. Contact:Joe Hassettjoeh@gregoryfca.commob:

610-787-0464

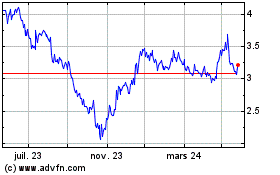

Aquafil (BIT:ECNL)

Graphique Historique de l'Action

De Oct 2024 à Nov 2024

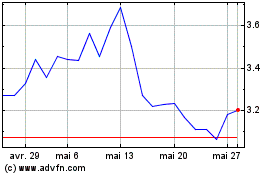

Aquafil (BIT:ECNL)

Graphique Historique de l'Action

De Nov 2023 à Nov 2024