Integra Gold Reports up to 97.8% Gold Recovery in Phase 3 Metallurgical Testing

25 Février 2014 - 3:25PM

Marketwired Canada

Press release highlights:

-- Gold recovery of up to 97.8% for the Parallel Zone composite samples

using a combination of gravity and Carbon-in-Leach ("CIL") cyanidation.

-- Test work completed by ALS Metallurgy ("ALS") in Kamloops, British

Columbia, with supervision by WSP Group ("WSP") from Val-d'Or, Quebec

-- Phase 3 focused on applying recovery processes consistent with existing

milling infrastructure in the region

Integra Gold Corp. (TSX VENTURE:ICG) ("Integra" or the "Company") is pleased to

announce it has completed its Phase 3 metallurgical testing program at its

Lamaque Gold Project in Val-d'Or, Quebec. The Phase 3 program was designed to

individually assess the metallurgical response of samples from the project's

four gold deposits using flowsheets that replicated the processes used by

various mills in the immediate vicinity of the Lamaque Project. The Company is

currently assessing the viability and availability of each of the mills and will

incorporate these results into its future plans.

"Results of this program confirm that gold at the Lamaque Project can be

efficiently recovered utilizing the same processing methodologies and flowsheets

used in existing milling facilities in the immediate vicinity. We will use this

positive metallurgical data to guide the next phase of our development plan,

which is to assess all options and determine the best fit for the Company's

needs moving forward. The fact that there are six potentially available mills

included as part of this study speaks volumes about the infrastructure

advantages this project has," commented Company President and CEO, Stephen de

Jong. "The recent test work indicates that metallurgical gold recoveries can be

optimized to over 95% which is consistent with what was achieved historically on

similar types of mineralization at the neighbouring Lamaque and Sigma mines.

Further metallurgical work is required for the Plug No. 4 material and we are

confident there is significant room for optimization. We do not anticipate this

will have a significant impact on our upcoming PEA as the initial phase of

proposed production will focus on the Triangle and Parallel Zones."

The following table give a summary of Phase 3 optimized recoveries using a 96

hour leach time:

Phase 3 Metallurgical Testing - Gold Recoveries versus Metallurgical Process

(96 hour retention time)

-----------------------------------------------------------------------

Clusters and Zones

----------------------------------------------

North Cluster South Cluster

-----------------------------------------------------------------------

Metallurgical Process Parallel Fortune Triangle Plug No. 4

-----------------------------------------------------------------------

Process 1 97.8% 96.6% 93.1% 87.6%

-----------------------------------------------------------------------

Process 2 97.1% 95.6% 92.9% 83.2%

-----------------------------------------------------------------------

Process 3 96.6% 97.1% 93.4% 85.1%

-----------------------------------------------------------------------

Process 4 85.8% 82.0% 71.1% 58.4%

-----------------------------------------------------------------------

Process 1 - Gravity concentration with CIL cyanide leach

Process 2 - Whole ore cyanide leach

Process 3 - Whole ore CIL cyanide leach

Process 4 - Flotation separation with cyanide leach of concentrate

(excluding leach of tails)

Summary of Phase 3 Metallurgical Testing

The metallurgical test program was completed by ALS on samples from the Lamaque

deposits in Val-d'Or, Quebec on behalf of Integra, with supervision by WSP from

Val-d'Or. The focus of this program was to test and compare four possible

flowsheets, mirroring existing milling infrastructure in the region, on

composites from four separate gold mineralized zones.

Four separate composites from the Parallel, Triangle, Fortune and No. 4 Plug

zones were prepared from crushed drill core. The four composites were prepared

to be at a median range of gold grade respective to each zone. Gold head assays

were conducted using a screened metallic assaying method due to the coarse

nugget effect of the gold in these deposits. The composites assayed 9.1, 8.8,

6.2 and 4.4 grams/tonne gold ("g/t Au") for the Parallel, Triangle, Fortune and

No. 4 Plug composites, respectively.

Four flowsheets were tested on each sample. The first involved a gravity

concentration followed by a Carbon-in-Leach ("CIL") cyanide leach of the gravity

tails. The second was a whole ore cyanide leach and the third was a whole ore

CIL. The fourth flowsheet involved a flotation separation (rougher and cleaner)

followed by a separate cyanide leach of the flotation concentrate. Gold

recoveries from the first three flowsheets were similar. Using these three

flowsheets, and a 96 hour leach time, gold recoveries were as followed:

Parallel Zone Composite: 96.6% to 97.8%

Triangle Zone Composite: 92.9% to 93.4%

Fortune Zone Composite: 95.6% to 97.1%

Plug No. 4 Zone Composite: 83.2% to 87.6%

Using these same three flowsheets but with a 48 hour leach time, gold

recoveries were as followed:

Parallel Zone Composite: 94.1% to 96.7%

Triangle Zone Composite: 89.3% to 90.2%

Fortune Zone Composite: 92.8% to 95.0%

Plug No. 4 Zone Composite: 82.7% to 86.1%

The main difference between flowsheet performances was related to reagent

consumption, with the CIL extractions consuming approximately twice as much

sodium cyanide. In comparing the first three flowsheets, recovery differences

were small enough that reagent consumptions and other economic factors relating

to the use of the different processing facilities would likely be more

significant than the metallurgical recovery differences.

The fourth flowsheet which involved gold recovery utilizing the flotation and

cyanide leaching flowsheet produced significantly lower recoveries. This

flowsheet, when not including the cyanide leach of the flotation tailings, had

gold recovery substantially lower than the other flowsheets tested. Reagent

consumptions for this flowsheet were also lower.

Testing Parameters

All flowsheets were tested with a primary grind sizing of 75um K80. Further

testing with various grind sizes may be used in the future to further optimize

test work.

The first flowsheet tested utilized a batch Knelson gravity concentrator with a

hand panning of the gravity concentrate. Tailings from this gravity

concentration underwent a 96 hour CIL cyanide test. The leaches were conducted

at a pH of 11.0, with a sodium cyanide concentration of 1,000 ppm and with 30

grams per liter of carbon added to the leach slurry.

The second and third flowsheets were similar. The second flowsheet involved a 96

hour whole ore leach using 1,000 ppm sodium cyanide and a pH of 11.0. The third

flowsheet used the same conditions as the second with the 96 hour leaches being

CIL tests with 30 grams per liter of carbon added to the leach slurry.

The fourth flowsheet utilized flotation separation with a rougher separation

followed by one stage of dilution cleaning. The flotation cleaner concentrate

was subjected to a cyanide leach at 2,000 ppm sodium cyanide at pH of 11.0 for

96 hours. The flotation separations were conducted at natural pH with Potassium

Amyl Xanthate (PAX) as a sulphide collector and Methyl Isobutyl Carbonyl (MIBC)

as the frother.

No. 4 Plug Composites Future Testing

The No. 4 Plug composite has shown slightly lower overall gold recoveries when

compared to material from other zones in all of the metallurgical processes

tested. Before additional metallurgical testing is performed, and in order to

fine-tune metallurgical recoveries for this zone, a mineralogical analysis of

this ore type will be conducted. In previous testing work (see press release

dated May 01, 2013 and July 25, 2013 on Phase 1 and 2 testing), finer grinding

and more intense leach conditions had shown to optimize and improve performance

significantly.

Project and Company Profile

Integra's Lamaque gold project is located in the heart of the Val-d'Or gold camp

in the Province of Quebec, Canada, approximately 550 km northwest of Montreal.

Quebec is rated one of the best mining jurisdictions in the world.

Infrastructure, human resources and mining expertise are readily available.

The Company's primary objective is to continue to prove up additional resources

while advancing the existing resource towards production. The project is divided

into three main clusters of mineralization, the North, South and West Cluster.

The North Cluster consists of the Parallel, Fortune, No. 5 Plug, and No. 3 Mine

zones and is located approximately 1 km from the South Cluster, which includes

the No. 4 Plug, Triangle and Triangle South zones. The Sixteen Zone and No. 6

Vein form the West Cluster.

Qualified Persons

The Lamaque exploration project is under the direct supervision of Herve

Thiboutot, Eng. and Senior Vice-President of the company, and Francois Chabot,

Eng. and Operations and Engineering Manager of the Company, both Qualified

Person ("QP") as defined by National Instrument 43-101, and Alain-Jean

Beauregard, P.Geo., Daniel Gaudreault, Eng., Geo. of Geologica Inc., and Michel

Garon, Eng., M.A.Sc. of WSP Group in Val-d'Or, Quebec, all three independent QP

as defined by National Instrument 43-101. The Company's QPs have reviewed the

technical content of this release.

Quality Assurance - Quality Control ("QA/QC")

Thorough QA/QC protocols are followed on the project including insertion of

duplicate, blank and standard samples in all drill holes. The core samples are

submitted directly to ALS Laboratory Group and Bourlamaque Labs in Val-d'Or for

preparation and analysis. Analysis is conducted on 1 assay-ton aliquots.

Analysis of Au is performed using fire assay method with atomic absorption

finish, with a gravimetric finish completed for samples exceeding 5 g/t Au, or a

metallic sieve assay for samples containing visible gold. When available the

gravimetric or metallic sieve assay results are used for the reported composite

intervals.

ON BEHALF OF THE BOARD OF DIRECTORS

Stephen de Jong, CEO & President

Follow Integra Gold On:

- Twitter: http://twitter.com/integragoldcorp

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that

term is defined in the policies of the TSX Venture Exchange) accepts

responsibility for the adequacy or accuracy of this news release.

Cautionary Note Regarding Forward Looking Statements:

No stock exchange, securities commission or other regulatory authority has

approved or disapproved the information contained on this presentation. This

presentation contains "forward-looking information" concerning Integra Gold

Corp.'s ("Integra" or the "Company") future financial or operating performance

and other statements that express management's expectations or estimates of

future developments, circumstances or results. Generally, forward-looking

information can be identified by the use of forward-looking terminology such as

"seeks", "believes", "anticipates", "plans", "continues", "budget", "scheduled",

"estimates", "expects", "forecasts", "intends", "projects", "predicts",

"proposes", "potential", "targets" and variations of such words and phrases, or

by statements that certain actions, events or results "may", "will", "could",

"would", "should" or "might" "be taken", "occur" or "be achieved".

Forward-looking statements included in this presentation include statements

regarding potential mineralization and mineral resources, the proposed mining

scenario for the South Lamaque Gold Project, including information with respect

to the supporting infrastructure, the potential life of mine, rates of

employment and the effects of steps taken to mitigate local impacts and the

expected completion dates of exploration and drilling, exploration results,

estimated and future exploration and administration expenditures, the completion

of scoping studies, preliminary economic assessment, pre-feasibility or

feasibility studies, and future plans and objectives of Integra. While all

forward-looking statements involve various risks and uncertainties, these

statements are based on certain assumptions that management of Integra believes

are reasonable, including that it will be able to obtain financing and on

reasonable terms, that its current exploration and other objectives can be

achieved, that its exploration and other activities will proceed as expected,

that its community and environmental impact procedures will work as anticipated,

that general business and economic conditions will not change in a material

adverse manner, that Integra will not experience any material accident, labour

dispute or failure or shortage of equipment, and that all necessary government

approvals for its planned exploration and potential development activities will

be obtained in a timely manner and on acceptable terms.

There can be no assurance that the forward-looking statements will prove to be

accurate and actual results and future events could differ materially from those

anticipated in such statements. Important factors that could cause actual

results to differ materially from the Integra's expectations include, among

others, the actual results of current exploration activities being different

than those anticipated by Integra, changes in project parameters as plans

continue to be refined, changes in estimated mineral resources, future prices of

metals, increased costs of labor, equipment or materials, availability of

equipment, failure of equipment to operate as anticipated, accidents, effects of

weather and other natural phenomena, risks related to community relations and

activities of stakeholders, and delays in obtaining governmental approvals or

financing. Although Integra has attempted to identify important factors that

could cause actual results to differ materially, there may be other factors that

cause results not to be as anticipated, estimated or intended. There can be no

assurance that such statements will prove to be accurate as actual results and

future events could differ materially from those anticipated in such statements.

Accordingly, readers should not place undue reliance on forward-looking

statements. Integra does not intend, and expressly disclaims any intention or

obligation to, update or revise any forward-looking statements whether as a

result of new information, future events or otherwise, except as required by

law.

FOR FURTHER INFORMATION PLEASE CONTACT:

Corporate Inquiries:

Integra Gold Corp.

Chris Gordon

chris@integragold.com

www.integragold.com

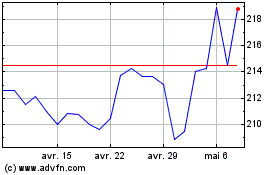

WSP Global (TSX:WSP)

Graphique Historique de l'Action

De Avr 2024 à Mai 2024

WSP Global (TSX:WSP)

Graphique Historique de l'Action

De Mai 2023 à Mai 2024