Aldi Chooses Parx for Hygiene and Cross Contamination Prevention in Meat and Poultry Section

01 Juillet 2019 - 9:51AM

Business Wire

PARX PLASTICS N.V. (Euronext: MLPRX) ("Parx" or the

"Company") is pleased to announce Aldi in USA has been

implementing shelf liners produced with the aid of the Parx

Plastics technologies.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20190701005338/en/

Aldi in USA has been implementing shelf

liners produced with the aid of the Parx Plastics technologies.

Hygiene is an important priority for supermarkets. On the one

hand it is to guarantee food safety on the shop floor and on the

other hand, the consumer is becoming increasingly critical.

Certainly, when it comes to hygiene and safety. A clean supermarket

contributes to a positive consumer experience.

Prevent clogging in drainage systems

An important area in the supermarket is the refrigerator

section. The Parx technology has already been thoroughly tested in

drainage systems of freezers and refrigerators in supermarkets in

the UK. Supermarket refrigeration display cabinets globally suffer

from a build of bacteria known as Pseudomonas. This type of

bacteria is known for its self-produced mucus that latch onto the

internal surfaces of the waste water drainage pipes where they

continue to grow and generate larger forms of biofilms and slime,

which eventually results in clogged drain pipes. Over a period of

time the buildup is so severe that it causes a full blockage of the

drainage pipe, results in water leaks, maintenance issues, service

call-outs and possible outbreaks of pathogens. Tests taking as long

as 12 to 14 months showed that integrating the Parx technologies in

these drainage systems created a sustainable anti-clogging solution

that can reduce call-outs by up to 100% over a period of time,

saving supermarket chains a lot of costs and disruption involved

with blocked drains. Keeping the freezers and refrigerator drain

systems cleaner and more hygienic in a sustainable way, replacing

the use of harmful chemicals.

Keep the shelves clean

Keeping the rest of the freezer or refrigerator clean is

something that many supermarkets have laid out in a periodic

cleaning scheme. These areas are notorious for collecting food

particles and should be cleaned out regularly. To make this task

easier supermarkets are fitting shelf-liners into their

refrigerators. These shelf liners are covering the entire shelf and

are often interlocking to fully cover the shelf surface. They are

easy to remove an have collected all the dirt build-up since the

previous cleaning. This means by taking out the shelf liner you do

not need to reach to the end of the freezer and a manageable

component can easily be cleaned and washed off outside of the

system. This makes it much easier to clean the shelves, so it can

be done easier, quicker and more regularly.

Preventing adherent cells

Leading the way to guarantee the utmost hygiene, Aldi in USA has

been implementing shelf liners produced with the aid of the Parx

Plastics technologies. These technologies are integrated in the

manufacturing process of the extruded sheets and have the ability

to prevent adhesion of biofilm and bacteria. The technology is

creating a surface with a build-in defense mechanism against

adherent cells, making sure the surfaces stay cleaner for

longer.

Innovative technology

The Parx technologies originally are derived from nature. It was

developed in an effort to copy the human immune system which

greatly relies on trace elements. Incorporating a trace element

into polymers, with an innovative method, delivers unique

characteristics mimicking the characteristics of the human skin.

The technology was recognized in its early stages by the European

Commission, marking the company as one of the top tech startups of

Europe. The technology was also picked up in the USA as an

innovation with the likely long-term significance, receiving a

World Technology Award in the materials category.

By adopting this technology, the (originally European)

discounter is taking a leading position with its stores in the US.

By adopting a shelf liner system with the Parx technologies

build-in, it has selected the cleanest and safest solution there is

available today. Securing the utmost hygiene in their stores.

Reducing cross-contamination

Back in 2011 UK food standards officials discovered that 40% of

packets of chicken in a range of supermarkets, convenience stores

and butchers were covered with bacteria on the outside. Of 20

packets of chicken studied, eight had food poisoning bacteria on

their wrapping. Findings like this drive an increasing amount of

attention to cross-contamination. There are fears that once handled

in a supermarket, the bacteria can be passed on through trolley

handles, shopping bags and transferred to other foods.

Making sure that cross-contamination from one package to the

shelf to another package is restrained, means going the extra mile

for the utmost food safety.

Hygiene determines the image of the supermarket and a clean shop

floor contributes to a welcoming appearance. Experience today is

the key word, where good hygiene is indispensable. Shops who

visibly pay attention to hygiene raise the consumers’ confidence

and that trust is essential for a good customer relationship.

Statement Regarding Forward-Looking Information

This press release contains forward-looking statements and

information that are based on the beliefs of management and reflect

the Company's current expectations. When used in this press

release, the words "estimate", "project", "belief", "anticipate",

"intend", "expect", "plan", "predict", "may" or "should" and the

negative of these words or such variations thereon or comparable

terminology are intended to identify forward-looking statements and

information. The forward-looking statements and information in this

press release includes information relating to the engagement of

Parx and the consideration payable to Parx. Such statements and

information reflect the current view of the Company. Risks and

uncertainties that may cause actual results to differ materially

from those contemplated in those forward-looking statements and

information.

By their nature, forward-looking statements involve known and

unknown risks, uncertainties and other factors which may cause our

actual results, performance or achievements, or other future

events, to be materially different from any future results,

performance or achievements expressed or implied by such

forward-looking statements.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20190701005338/en/

Michael Van der Jagt CEO Parx Plastics NV

Groot Handelsgebouw Stationsplein 45, Unit A4.004 3013 AK Rotterdam

The Netherlands info@parxplastics.com +31(0)103400095

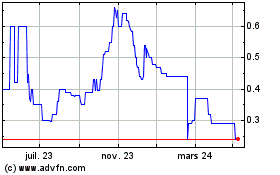

Parx Materials NV (EU:MLPRX)

Graphique Historique de l'Action

De Nov 2024 à Déc 2024

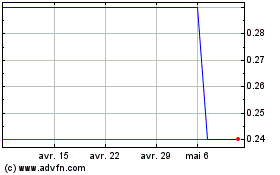

Parx Materials NV (EU:MLPRX)

Graphique Historique de l'Action

De Déc 2023 à Déc 2024