Applied Materials Accelerates Chip Defect Review with Next-Gen eBeam System

19 Février 2025 - 10:05PM

Applied Materials, Inc. today introduced a new defect review system

to help leading semiconductor manufacturers continue pushing the

limits of chip scaling. The company’s SEMVision™ H20 system

combines the industry’s most sensitive electron beam (eBeam)

technology with advanced AI image recognition to enable better and

faster analysis of buried nanoscale defects in the world’s most

advanced chips.

eBeam imaging has long been an important tool for examining

defects that are too small to be seen with optical techniques. Its

ultra-high resolution enables analysis of the tiniest imperfections

in a sea of billions of nanoscale circuit patterns. Traditionally,

optical techniques are used to scan a wafer for potential defects,

and then eBeam is deployed to better characterize these defects. In

the emerging “angstrom era” – where the smallest chip features can

be just a few atoms thick – it is becoming increasingly difficult

to differentiate true defects from false alarms.

At today’s most advanced nodes, optical inspection creates much

denser defect maps, which can require as much as a 100X increase in

the number of defect candidates delivered to eBeam review. Process

control engineers increasingly need defect review systems that can

analyze exponentially more samples while maintaining the speed and

sensitivity required for high-volume production.

“Our new SEMVision H20 system allows the world’s leading

chipmakers to better separate the signal from the noise amidst

massive amounts of data provided by inspection tools,” said Keith

Wells, Group Vice President of Imaging and Process Control at

Applied Materials. “By combining advanced AI algorithms with the

superior speed and resolution of our innovative eBeam technology,

our system enables rapid identification of the smallest defects

buried deep in 3D device structures, delivering faster and more

accurate inspection results that can improve factory cycle time and

yield.”

Applied’s new eBeam technology is critical for complex 3D

architecture inflections required to manufacture logic chips at the

2nm node and beyond – including new Gate-All-Around (GAA)

transistors – as well as the formation of higher-density DRAM and

3D NAND memories. Applied’s SEMVision H20 defect review system has

been adopted by leading logic and memory chipmakers for emerging

technology nodes.

The new SEMVision H20 system leverages two significant

innovations to classify defects with remarkable accuracy, while

delivering results as much as 3X faster than today’s most advanced

techniques.

- Next-generation CFE technology: Applied’s

“cold field emission” (CFE) technology is a breakthrough in eBeam

imaging that enables sub-nanometer resolution for identifying the

smallest buried defects. Operating at room temperature, CFE

produces a narrower beam with more electrons, thereby increasing

nanoscale image resolution by up to 50 percent and imaging speed by

up to 10X compared to conventional thermal field emission (TFE)

technology. With SEMVision H20, Applied is introducing the second

generation of its CFE technology, delivering even faster throughput

while maintaining the industry’s highest sensitivity and

resolution. This faster imaging speed provides increased coverage

across each wafer, allowing chipmakers to gather the same amount of

information in one third of the time.

- Deep learning AI image models: SEMVision H20

uses deep learning AI capabilities for automatic extraction of true

defects from false “nuisance” defects. Applied’s proprietary deep

learning network is continuously trained with data from a

chipmaker’s fab and sorts the defects into a distribution including

voids, residues, scratches, particles and dozens of other defect

types, enabling more accurate and efficient defect

characterization.

Applied’s SEMVision product family is the most advanced and

widely used eBeam review system in the world. The new SEMVision H20

extends this leadership by combining next-generation CFE technology

and advanced AI models to deliver faster and more accurate defect

analysis, allowing chipmakers to accelerate chip development and

make greater use of eBeam technology in high-volume

manufacturing.

About Applied MaterialsApplied Materials, Inc.

(Nasdaq: AMAT) is the leader in materials engineering solutions

used to produce virtually every new chip and advanced display in

the world. Our expertise in modifying materials at atomic levels

and on an industrial scale enables customers to transform

possibilities into reality. At Applied Materials, our innovations

make possible a better future. Learn more at

www.appliedmaterials.com.

Applied Materials Contact:Ricky Gradwohl

(editorial/media) 408.235.4676Liz Morali (financial community)

408.986.7977

A photo accompanying this announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/80511701-73c9-406d-8cb0-aeb0793e4497

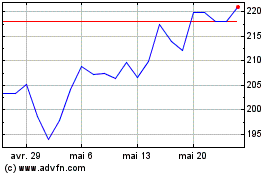

Applied Materials (NASDAQ:AMAT)

Graphique Historique de l'Action

De Fév 2025 à Mar 2025

Applied Materials (NASDAQ:AMAT)

Graphique Historique de l'Action

De Mar 2024 à Mar 2025