Celebrating 25 Years of Santoprene TPEs; ExxonMobil Chemical's Elastic Plastic Serves Thousands of CustomersThere are currently

27 Juin 2006 - 9:05PM

Business Wire

Research to create a new material for an injection-molded tire

resulted in the commercialization of Santoprene(TM) thermoplastic

elastomer (TPE) 25 years ago. Today, the Santoprene product

portfolio has over 300 grades that are used by thousands of

customers across the globe in the automotive, food and beverage,

consumer electronics, electrical, and appliance markets. This

resourceful, innovative and committed pioneer continues to be

recognized today as the global leader in engineered TPEs. This

article celebrating 25 years of Santoprene brand TPEs charts the

development of the brand from the obstacles it faced to the

successes it enjoys with an outlook toward continued growth.

Overcoming early hurdles The unique material that became Santoprene

TPE exhibited the performance characteristics of rubber and the

processing ease of a plastic, with complementary benefits. But it

was not an overnight success. "Initially we targeted the processors

that manufactured finished parts from rubber," said Bob Liskiewicz,

global sales manager for ExxonMobil Chemical's Specialty Elastomers

Business. "The new material got a luke-warm reception from the

rubber industry. Target customers weren't prepared to work with a

material that was fully compounded or invest in the new equipment

they needed to process it. We were excited about the opportunities

of the material, but the rubber industry was reluctant to invest in

a new business." A revised business strategy focused on the

customers of the rubber processors. Approaching automotive original

equipment manufacturers (OEMs) and appliance manufacturers proved

successful. "We convinced them that we had an interesting new

material. Now we had to encourage the creation of a supply chain

that could manufacture the parts," explained Liskiewicz. The clear

message that got the interest of the OEMs was cost savings.

Santoprene TPEs' faster part-production cycle times, lower weight

and ease of production all contributed to lower part costs. "We

established Rubber Conversion Economics, which compared every

aspect of producing a part in a traditional rubber material with

Santoprene TPE. We demonstrated that an OEM could save a

significant percentage on the cost of the final part if they

converted to our TPE," said Liskiewicz. In addition to cost

savings, the establishment of unrivalled technical support

capabilities and the manufacturing capabilities to provide

materials of consistent quality across the world led to a

successful global business. Early successes The brand achieved an

important early application success in the automotive sector. While

the rack-and-pinion boot only costs a small percentage of the

steering system to manufacture, it plays a critical role in

protecting the system. The ability of Santoprene TPE to improve

flex life, fluid resistance and sealability of the boot is key to

the success of this application. The reduction in manufacturing

costs is an added bonus. "The application has been so successful

that it can probably be found in four out of five cars on the road

today," explained Liskiewicz. In the appliance sector, the business

worked with OEMs to manufacture components -- often seals -- for

household appliances such as dishwashers and washing machines. A

dishwasher sump boot made with Santoprene TPE was an early success

as it was installed in many major brands and models. Again the

functional benefits of Santoprene TPE -- good sealing and

resistance to heat and fluids -- were important. The elastomer's

sealing capabilities also led to early successes in the domestic

and high-rise construction sectors in applications such as window

seals, caster wheels, tubing and small hose parts, electrical

connectors and coatings for wire & cables. Santoprene TPE also

found success in the highly demanding medical industry where it is

used as a gasket on syringe plungers. Sound strategies At the

outset, the business implemented an astute intellectual property

strategy that extended Santoprene products' commercial longevity as

competitive products entered the market. As these products became

available, the strong brand values that were established and built

from the earliest days demonstrated that it takes more than

products to help make customers successful in rubber replacement

and other TPE applications. Combining performance improvements and

cost reductions with the best global support in the industry --

logistics, inventory in-hand, 24-48 hour delivery, consistent

quality and extensive technical support -- have all become key

components in the success of the business. It established a 98

percent on-time delivery rate for customers from Boston to

Barcelona to Beijing. "We serve thousands of customers with an

extra special level of service day after day," added Liskiewicz. As

the business worked with OEMs, it started to bring work to

processors, creating a strong loyalty among them. "We collaborate

and dedicate resources to companies often before they are

customers. Whether it's market knowledge, design assistance or

supply chain expertise, we bring all our experience to bear to help

companies design, develop and introduce new products to market. We

offer the immediate technical and design support of our engineering

specialists through web conferencing, online collaboration, our

AnswerPerson(TM) service and face-to-face," said Liskiewicz. "As a

result, we have achieved double-digit growth in volume and sales

for most of the past 25 years." As another demonstration of its

commitment to the industries it serves, the Santoprene specialty

products business is certified to the same standards as some of its

customers and their customers. For example, it recently achieved

certification to the globally accepted automotive industry quality

standard ISO/TS 16949:2002. Continued growth The business expanded

in the mid 1990s when it began to promote the use of Santoprene TPE

to enhance the way products look or how they feel to the touch.

This "soft-touch" concept enabled the business to develop extensive

use of Santoprene elastomers in grips for consumer products such as

ski poles, gardening and power tools, razors, toothbrushes and

pens. The business worked with product designers who began to use

Santoprene TPE for the aesthetic effects it produces -- soft touch,

color, texture and special effects. "This extra dimension opened up

the consumer market for us," said Liskiewicz. In the late 1990s,

the business developed new opportunities in the automotive industry

by proving to automotive OEMs that TPEs were a viable alternative

to thermoset rubber for sealing systems. Today, automotive OEMs

fully recognize and embrace the opportunities for improved

performance, weight reductions that boost fuel efficiency, and

parts cost savings that are achieved using Santoprene TPE. The use

of Santoprene TPE also enables soft/hard material combinations,

depending on the performance requirements of each part of the seal.

Other automotive OEMs have come to appreciate the benefits of

changing to TPEs. An exciting future "Looking forward we see

potential for growth in developing countries, new applications,

product development and modular systems," said Liskiewicz. China

and other countries in Asia, Central Europe and Latin America

represent growth markets. The Santoprene brand is established in

Japan through commercial links with major OEMs in the automotive

sector. Establishing a presence in China and helping a customer

there create a first commercial success with Santoprene TPE 20

years ago, the business is ideally positioned to benefit from this

rapidly evolving market. New applications will continue to drive

growth. Many of the consumer markets are only just starting to

truly appreciate the benefits of Santoprene products and there are

still excellent growth opportunities in the automotive sector. New

products are in development as the business researches compounds or

hybrids of TPEs and TPVs to match target performance requirements.

New Santoprene TPE bonding grades maximize the potential of

overmolding technology to eliminate the need for adhesives and

mechanical interlocks to combine different materials. As part of

ExxonMobil Chemical's Specialty Elastomers Business, there is also

a broad portfolio of elastomer products on which to draw. This has

recently led to the adoption of a modular approach where the

performance requirements of a whole system, such as a car door

system, are being considered and solutions proposed. "Without

doubt, the underlying success of the business has been a singular

focus on the customer, delivered by exceptional people with an

inquiring and responsive attitude. Adding value to a customer's

product helps them bring value to their customers. This is, and

always will be, at the core of the development and growth of the

Santoprene brand," concluded Liskiewicz. About ExxonMobil Chemical

ExxonMobil Chemical is a global leader in technology, product

quality and customer service with petrochemical manufacturing

and/or marketing operations in more than 150 countries around the

world. Its products include olefins, aromatics, fluids, synthetic

rubber, polyethylene, polypropylene, oriented polypropylene

packaging films, plasticizers and synthetic lubricant basestocks.

To find out more about ExxonMobil Chemical's Santoprene rubber,

visit www.santoprene.com. To find out more about ExxonMobil

Chemical, visit www.exxonmobilchemical.com. Note to Editors: 1. The

term "ExxonMobil Chemical" refers collectively to some or all of

the companies affiliated with Exxon Mobil Corporation which have

chemical manufacturing and/or marketing operations around the

world. 2. ExxonMobil, the ExxonMobil logo, the "Interlocking X" and

Santoprene are trademarks or registered trademarks of Exxon Mobil

Corporation.

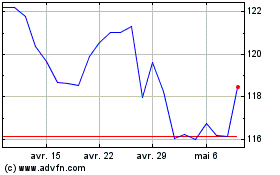

Exxon Mobil (NYSE:XOM)

Graphique Historique de l'Action

De Juin 2024 à Juil 2024

Exxon Mobil (NYSE:XOM)

Graphique Historique de l'Action

De Juil 2023 à Juil 2024