Mkango Resources Ltd. (AIM/TSX-V: MKA) (the “Company” or “Mkango”)

is pleased to announce the first production of recycled rare earth

magnets in the United Kingdom on commercial scale magnet

manufacturing equipment in over 20 years, a major milestone in

securing critical raw materials for the energy transition.

HIGHLIGHTS:

- First production runs of

short-loop recycled rare earth magnets completed at the Tyseley

Energy Park (“Tyseley”) rare earths hub in Birmingham, UK -

commercial production targeted for mid-2024

- First UK production of

sintered rare earth magnets on commercial scale equipment in over

20 years – new domestic source to catalyse electric vehicle, wind

turbine and other clean technology industries

- Tyseley scale-up

underpinned by successful piloting at University of Birmingham with

over 3,000 finished rare earth magnets produced from piloting to

date

- Strong interest for

recycled magnets from potential customers and for recycling

solutions from original equipment manufacturers (“OEMs”), and

automotive and recycling companies

- Hydrogen Processing of

Magnet Scrap (“HPMS”) technology being commercialised by HyProMag

is far cleaner and more energy efficient than traditional magnet

recycling processes

- HyProMag

was selected by the Minerals Security Partnership

(“MSP”) for support as one of its key projects given its strong

potential to contribute towards the development of responsible

critical mineral supply chains

Production of recycled rare earth magnets at

Tyseley is being developed by the University of Birmingham and

HyProMag, which is owned by Mkango’s 79.4% held subsidiary,

Maginito Limited (“Maginito”). Further production runs are planned

in the coming weeks to provide customer and project partner

samples.

Commercial production at Tyseley is targeted for

mid-2024, with initial throughput targeted at 20 tonnes per annum

(“tpa”) rare earth magnets and alloys, scaling up to a minimum of

100tpa in subsequent months. Larger scale up scenarios of up to

1,000tpa are currently being evaluated.

HyProMag is the main industrial partner for the

Tyseley development and the exclusive licencee for underlying HPMS

technology, developed at the University of Birmingham and now being

commercialised by HyProMag. HPMS is a revolutionary new recycling

technology that preserves the quality of the original magnets for

reprocessing; a far cleaner and more energy efficient process than

the traditional dismantling, thermal demagnetisation and cleaning

processes and lends itself to automated and efficient processing.

The resulting recycled magnets are being made to recognised

industrial grades.

The Tyseley development forms the basis for the

2024 development of magnet recycling and manufacture in Germany by

HyProMag GmbH and for the 2025/2026 development of a multi-spoke

and hub operation in the United States through the joint venture

with CoTec Holdings Ltd (“CoTec”).

Commissioning of the remaining equipment and

infrastructure at Tyseley is expected in the coming weeks,

underpinning the subsequent transition to commercial production.

For these initial production runs, the recycled raw material feed

was derived from wind turbine magnets, voice coil assemblies from

hard disk drives and production scrap which was processed through

the existing recycling pilot plant commissioned in 2022 at the

University of Birmingham, and then transported for short loop

magnet manufacture at Tyseley.

Will Dawes, Chief Executive of Mkango

said: “This is a major milestone for the Company, HyProMag

and for the UK, creating a strong platform to advance to commercial

production and for the scale-up and roll-out of HPMS technology

into Germany, United States and other jurisdictions. HyProMag’s

recycling technology has major competitive advantages versus other

recycling technologies, and is a key enabler for the cost effective

and energy efficient separation and recycling of rare earth

magnets, avoiding the need for dismantling, and enabling the

production of magnets with a significantly reduced carbon

footprint.”

Nick Mann, Operations General Manager of

HyProMag said: “Beginning production on commercial scale

equipment is very exciting for all of us at HyProMag. We are

receiving strong market interest to begin delivering recycled

magnets to customers at scale – being able to start that over the

coming months will be extremely positive. We also look

forward to implementing the lessons learned as we see equipment

arriving in Germany next year and in the USA soon afterwards.”

Professor Allan Walton, Head of the

Magnetic Materials Group, University of Birmingham, and founding

Director of HyProMag said: “A huge amount of work has been

carried out over the last year on the existing pilot plant at the

University of Birmingham to produce a spectrum of NdFeB magnets

with a range of magnetic grades. This has allowed us to test

recycled magnets in a range of products for the first time with

extremely encouraging results. The installation of the new

equipment at Tyseley Energy Park has allowed us to prove that these

properties can be achieved on a commercial scale for the first time

on automated equipment. This is a massive step forward and

re-introduces commercial sintered magnet manufacturing back into

the UK for the first time in over 20 years”.

HyProMag is receiving strong interest for

recycled magnets from potential customers, underpinning the

transition to commercial operations, and for recycling solutions

from original equipment manufacturers (“OEMs”), and automotive and

recycling companies looking for a low cost and energy efficient

circular solution for magnet recycling that does not require

dismantling – HyProMag’s patented HPMS technology provides the

solution.

The magnets produced at Tyseley were of

commercial grade, featuring a square loop with good coercivity

(resistance to demagnetisation) and remanence (magnetic strength),

which are key measures of magnetic performance.

Apart from providing feed during the

commissioning phase of the Tyseley development, the pilot plant at

the University of Birmingham has enabled the testing of a broad

variety of scrap streams and the production of a wide range of

products since its commissioning in 2022, generating operating

information to support the scale-up and commercialisation of

operations. Furthermore, over 3,000 finished rare earth magnets

have been produced to date by HyProMag and the University of

Birmingham from recycled HPMS powder produced for project partners

and potential customers from the pilot scale equipment. These

magnets are being tested in a wide range of applications including

multiple automotive, aerospace, electronics applications, and

others planned, providing valuable marketing and technical

information to further support the scale-up and commercialisation

of operations.

Apart from the production of finished magnets,

the University of Birmingham pilot plant has also produced alloys

for remelt testing and chemical processing, maximising the

flexibility of the product suite and the ability to process

different scrap streams. Mkango is also developing a further pilot

plant at Tyseley for long loop recycling via a chemical process,

which complements the HyProMag short loop recycling process and

will also be commissioned in the coming weeks. Material for

chemical processing, including swarf (the powder produced from

grinding and finishing magnets), will either be processed in-house

by Mkango, or in partnership with third parties.

About HyProMagHyProMag

(www.hypromag.com) is 100 per cent owned by Maginito Limited, which

is owned on a 79.4/20.6 basis by Mkango and CoTec. HyProMag is

commercialising rare earth magnet recycling using Hydrogen

Processing of Magnet Scrap (“HPMS”) technology in the UK, Germany

and United States, with first production in the UK this year,

Germany in 2024 and the United States in 2025/2026.

HPMS technology was developed at the University

of Birmingham, underpinned by approximately US$100 million of

research and development funding, and has major competitive

advantages versus other rare earth magnet recycling technologies,

which are largely focused on chemical processes but do not solve

the challenges of liberating magnets from end-of-life scrap streams

– HPMS provides the solution. HyProMag’s company presentation can

be viewed via the following link: HyProMag Corporate

Presentation

HyProMag’s HPMS recycling technology was

selected by the Minerals Security Partnership (“MSP”) for support

as one of its key projects. The technology was selected by the MSP

because the MSP determined its strong potential to contribute

towards the development of responsible critical mineral supply

chains.

The MSP was formed in 2022 by 14 governments and

aims to ensure adequate supplies of minerals such as rare earths to

meet net zero-carbon goals. It aims to support public and private

sector investments building diverse, secure, and responsible global

critical minerals supply chains.

Having commissioned the UK’s first rare earth

magnet recycling pilot plant at the University of Birmingham in

2022, as featured on BBC Midlands News:

https://youtu.be/9P-dsNCffWw?si=pQQeLDv0zV8kdnbM, alongside the

UK’s only facility to make sintered rare earth magnets, HyProMag,

together with the University of Birmingham, are developing a

large-scale recycling and magnet manufacturing plant at Tyseley

Energy Park, Birmingham. This £4.3 million (C$7.3 million) project

is being funded by Driving the Electric Revolution, an Industrial

Strategy Challenge Fund challenge delivered by UK Research and

Innovation (“UKRI”).

About Mkango Resources

Ltd.

Mkango's corporate strategy is to develop new

sustainable primary and secondary sources of neodymium,

praseodymium, dysprosium and terbium to supply accelerating demand

from electric vehicles, wind turbines and other clean technologies.

This integrated Mine, Refine, Recycle strategy differentiates

Mkango from its peers, uniquely positioning the Company in the rare

earths sector. Mkango is listed on the AIM and the TSX-V.

Mkango is developing its flagship Songwe Hill

rare earths project (“Songwe”) in Malawi with a Definitive

Feasibility Study completed in July 2022 and an Environmental,

Social and Health Impact Assessment approved by the Government of

Malawi in January 2023. Discussions regarding the Mine Development

Agreement (“MDA”) for Songwe Hill are ongoing with the Government

of Malawi.

In parallel, Mkango and Grupa Azoty PULAWY,

Poland's leading chemical manufacturer have agreed to work together

towards development of a rare earth separation plant at Pulawy in

Poland (the “Pulawy Separation Plant”) to process the purified

mixed rare earth carbonate produced at Songwe Hill.

Through its ownership of Maginito

(www.maginito.com), Mkango is also developing green technology

opportunities in the rare earths supply chain, encompassing

neodymium (NdFeB) magnet recycling as well as innovative rare earth

alloy, magnet, and separation technologies. Maginito is owned 79.4

per cent by Mkango and 20.6 per cent by CoTec. It is focused on

developing green technology opportunities in the rare earths supply

chain, encompassing neodymium (NdFeB) magnet recycling as well as

innovative rare earth alloy, magnet, and separation

technologies.

Maginito holds a 100 per cent interest in

HyProMag and a 90 per cent direct and indirect interest (assuming

conversion of Maginito’s convertible loan) in HyProMag GmbH,

focused on short loop rare earth magnet recycling in the UK and

Germany, and a 100 per cent interest in Mkango Rare Earths UK Ltd

(“Mkango UK”), a company focused on long loop rare earth magnet

recycling in the UK via a chemical route. CoTec and Maginito have

also agreed to form a 50:50 joint venture in relation to the

roll-out of rare earth magnet recycling into the United States,

with feasibility study and development costs funded by CoTec.

Mkango also has an extensive exploration

portfolio in Malawi, including the Mchinji rutile exploration

project, the Thambani uranium-tantalum-niobium-zircon project and

Chimimbe nickel-cobalt project.

For more information, please visit www.mkango.ca

Market Abuse Regulation (MAR)

Disclosure

The information contained within this

announcement is deemed by the Company to constitute inside

information as stipulated under the Market Abuse Regulations (EU)

No. 596/2014 ('MAR') which has been incorporated into UK law

by the European Union (Withdrawal) Act 2018. Upon the publication

of this announcement via Regulatory Information Service, this

inside information is now considered to be in the public

domain.

Cautionary Note Regarding

Forward-Looking Statements

This news release contains forward-looking

statements (within the meaning of that term under applicable

securities laws) with respect to Mkango. Generally, forward looking

statements can be identified by the use of words such as

“targeted”, “plans”, “expects” or “is expected to”, “scheduled”,

“estimates” “intends”, “anticipates”, “believes”, or variations of

such words and phrases, or statements that certain actions, events

or results “can”, “may”, “could”, “would”, “should”, “might” or

“will”, occur or be achieved, or the negative connotations thereof.

Readers are cautioned not to place undue reliance on

forward-looking statements, as there can be no assurance that the

plans, intentions or expectations upon which they are based will

occur. By their nature, forward-looking statements involve numerous

assumptions, known and unknown risks and uncertainties, both

general and specific, that contribute to the possibility that the

predictions, forecasts, projections and other forward-looking

statements will not occur, which may cause actual performance and

results in future periods to differ materially from any estimates

or projections of future performance or results expressed or

implied by such forward-looking statements. Such factors and risks

include, without limiting the foregoing, the availability of (or

delays in obtaining) financing to develop Songwe Hill, and the

various recycling palnts in the UK, Germany and the US as well as

the separation plant in Poland, governmental action and other

market effects on global demand and pricing for the metals and

associated downstream products for which Mkango is exploring,

researching and developing, geological, technical and regulatory

matters relating to the development of Songwe Hill, the ability to

scale the HPMS and chemical recycling technologies to commercial

scale, competitors having greater financial capability and

effective competing technologies in the recycling and separation

business of Maginito and Mkango, availability of scrap supplies for

recycling activities, government regulation (including the impact

of environmental and other regulations) on and the economics in

relation to recycling and the development of the various recycling

and separation plants of Mkango and Maginito and future investments

in the United States pursuant to the cooperation agreement between

Maginito and CoTec, the outcome and timing of the completion of the

feasibility studies, cost overruns, complexities in building and

operating the plants, and the positive results of feasibility

studies on the various proposed aspects of Mkango’s, Maginito’s and

CoTec’s activities. The forward-looking statements contained in

this news release are made as of the date of this news release.

Except as required by law, the Company disclaims any intention and

assume no obligation to update or revise any forward-looking

statements, whether as a result of new information, future events

or otherwise, except as required by applicable law. Additionally,

the Company undertakes no obligation to comment on the expectations

of, or statements made by, third parties in respect of the matters

discussed above.

| For

further information on Mkango, please contact: |

|

| |

|

| Mkango

Resources Limited |

|

| |

|

| William

Dawes |

Alexander

Lemon |

| Chief Executive Officer |

President |

| will@mkango.ca |

alex@mkango.ca |

| Canada: +1 403 444 5979 |

|

| www.mkango.ca |

|

| @MkangoResources |

|

| |

|

| SP Angel Corporate Finance LLP |

|

| Nominated Adviser and Joint Broker |

|

| Jeff Keating, Kasia Brzozowska |

|

| UK: +44 20 3470 0470 |

|

| |

|

| Alternative Resource Capital |

|

| Joint Broker |

|

| Alex Wood, Keith Dowsing |

|

| UK: +44 20 7186 9004/5 |

|

| |

|

| Tavistock Communications |

|

| PR/IR Adviser |

|

| Jos Simson, Cath Drummond |

|

| UK: +44 (0) 20 7920 3150 |

|

| mkango@tavistock.co.uk |

|

| |

|

The TSX Venture Exchange has neither

approved nor disapproved the contents of this press release.

Neither the TSX Venture Exchange nor its Regulation Services

Provider (as that term is defined in the policies of the TSX

Venture Exchange) accepts responsibility for the adequacy or

accuracy of this release.

This press release does not constitute an offer

to sell or a solicitation of an offer to buy any equity or other

securities of the Company in the United States. The securities of

the Company will not be registered under the United States

Securities Act of 1933, as amended (the "U.S. Securities Act") and

may not be offered or sold within the United States to, or for the

account or benefit of, U.S. persons except in certain transactions

exempt from the registration requirements of the U.S. Securities

Act.

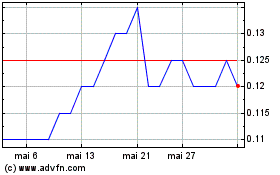

Mkango Resources (TSXV:MKA)

Graphique Historique de l'Action

De Avr 2024 à Mai 2024

Mkango Resources (TSXV:MKA)

Graphique Historique de l'Action

De Mai 2023 à Mai 2024